English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

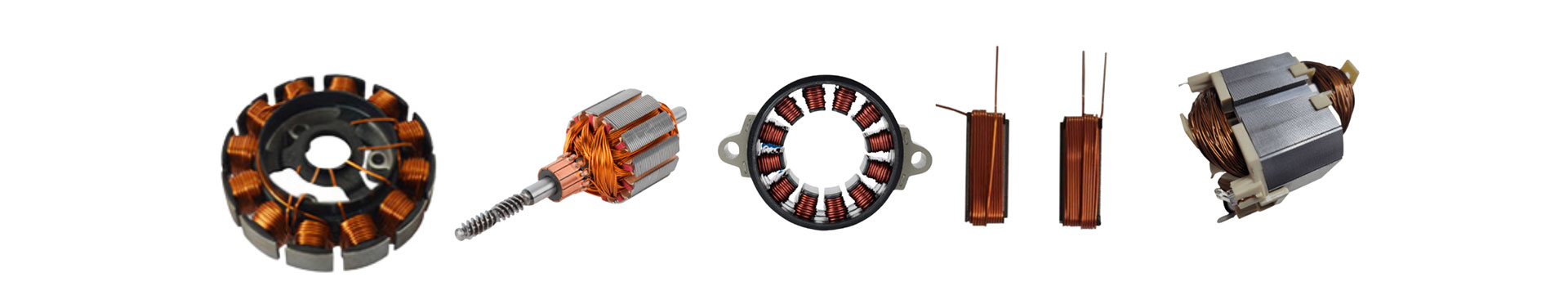

Vacuum Cleaner Brush Rotor Production Line

Vacuum cleaner brush rotor production line achieves high-efficiency, high-quality motor production through automated equipment and precision process flow, ensuring product reliability and performance. You are welcomed to come to our factory to buy the latest selling, low price, and high-quality Vacuum cleaner brush rotor production line. We look forward to cooperating with you.

Send Inquiry

Specification OfVacuum cleaner brush rotor production line:

|

Device Name |

Quantity |

Device Function |

|

Three-in-one press machine |

1 |

Pressing of core, shaft, end plate, commutator |

|

Slot lining paper inserting machine |

1 |

Insulating paper insertion |

|

High-speed winding spot welding machine |

3 |

Winding, commutator welding |

|

Slot wedge paper inserting machine |

1 |

Slot wedge paper insertion |

|

Comprehensive testing machine |

1 |

Rotor inspection |

|

C-type and E-type retaining ring pressing machine |

1 |

Circlip press-fitting |

|

Paint dripping machine |

1 |

Rotor painting |

|

Cooling machine |

1 |

Rotor cooling to room temperature |

|

Double-station precision turning machine |

1 |

Commutator turning |

|

Five-station weight removal and balancing machine |

1 |

Weight removal and balancing |

|

Double-station bearing pressing machine |

1 |

Bearing press-fitting |

|

Unloading and packing machine |

1 |

Finished product unloading |

Production line features:

1. Design features

The Vacuum cleaner brush rotor production line adopts modular equipment to meet the needs of flexible and intelligent production. It has many production line detection tools and can achieve full control of product quality.

2. Data processing

The Vacuum cleaner brush rotor production line can provide MES management system and realize digital production management.

3. Safety specifications

The Vacuum cleaner brush rotor production line is equipped with a transparent protective cover and an electronic safety module.

4. Remote service

The Vacuum cleaner brush rotor production line can achieve remote debugging and monitoring (customer authorization).

5. Appearance features

The equipment adopts the same high appearance design, which is beautiful, simple and atmospheric.

6. Scope of application

Vacuum cleaner rotor, power tool rotor, push rod motor rotor, etc.

7. Production line efficiency

Efficiency: 8s/PCS

8. Staffing

Employees: 1 person.