English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

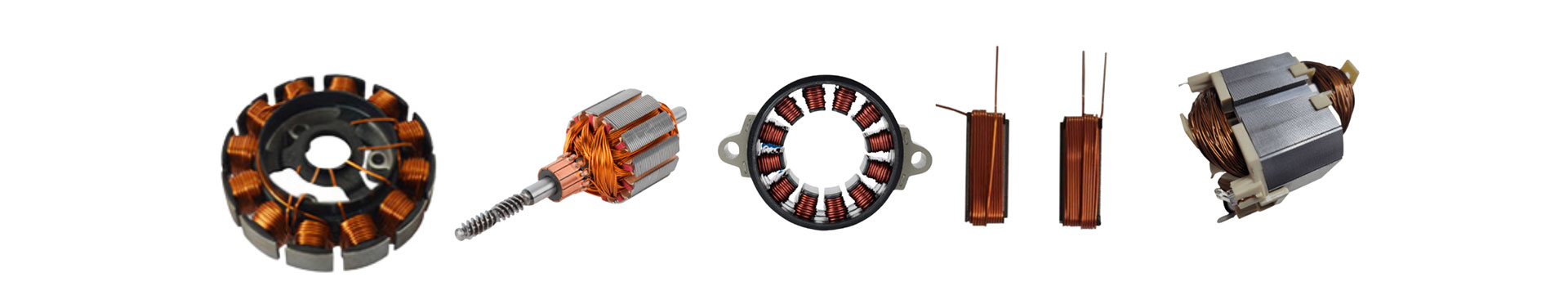

Rotor Pressure Commutator Machine with Conveyor Line

As a professional high quality SHUAIRUI® Rotor Pressure Commutator Machine with Conveyor Line manufacture, you can rest assured to buy Rotor Pressure Commutator Machine with Conveyor Line from our factory and we will offer you the best after-sale service and timely delivery.

Send Inquiry

SHUAIRUI® Rotor Pressure Commutator Machine with Conveyor Line

Equipment introduction:

1.This machine is used for the press-fitting process of the rotor commutator.

2.Manually add raw materials, and automatically complete feeding, dividing, positioning, and entering the commutator. It will be sent out automatically after pressing.

3.Press-in method: servo press-in.

4.Maximum output force: 3T.

5.Press-in progress: ±0.1mm.

6.The pressure monitoring system is equipped during the press-fitting process. When the pressure is too large or too small and exceeds the set force, it will automatically enter the defective product area.

7.Equipped with defective product recycling area.

8.The feeding method of the commutator; the two methods of vibrating plate and material tower are optional.

9.The commutator is pressed in without damage, and the angle deviation of the commutator is guaranteed to be ±0.3.

10.Working air pressure; 0.5-0.7MPa.

11.Applicable fields: rotors of electric tools, rotors of garden tools, rotors of vacuum cleaner motors, rotors of small household appliances, rotors of water pumps, rotors of automobile condenser fans, rotors of blower motors, rotors of push rod motors, rotors of electric forklift motors, rotors of glass lift motors, rotors of motors of automobile oil pumps , car window motor rotor, printer motor rotor, sewing machine motor rotor and other fields.