English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

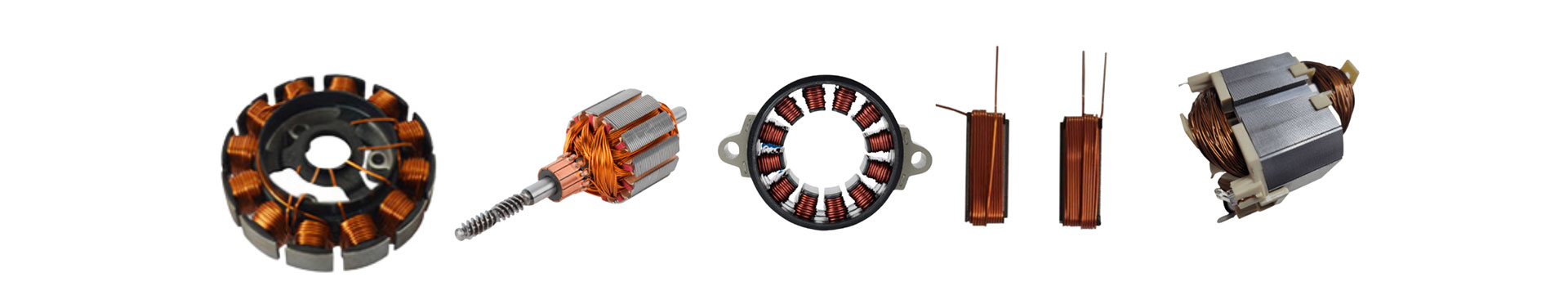

Rotor Single Station Finishing Machine

Send Inquiry

PDF DownLoad

SHUAIRUI® Rotor Single Station Finishing Machine

Equipment introduction:

1.This machine is used for the finishing process of rotors.

2.Full servo control effectively guarantees the turning quality (such as the surface roughness of the knife pattern, etc.).

3.The V-frame is equipped with a refueling and lubrication system, the number of which can be set, automatic refueling on a regular basis, and control of the amount of refueling.

4.Work efficiency ≤ 12S, turning 2 knives.

5.Single feed amount:

6.Rough turning: flat knife ≤ 0.07mm (one side).

7.Fine turning: flat knife ≤ 0.03mm (one side).

8.The chip suction effect is good, and the chip suction rate can reach 90% when the machine is equipped with a turning tool.

9.Loading, clamping, turning, blanking, and burr brushing are fully automatic.

10.Cast iron table top, diamond V-shaped frame, full servo drive high-precision moving parts.

11.Turning accuracy: Roundness: ≦0.003mm.

12.Inter-chip runout: ≤0.003mm.

13.Surface roughness: ≦Ra0.4- Ra1.3 (different process requirements can be adjusted).

14.High turning precision and stable turning quality.

15.Working air pressure: 0.5-0.7MPa.

16.Applicable fields: rotors of electric tools, rotors of garden tools, rotors of vacuum cleaner motors, rotors of small household appliances, rotors of water pumps, rotors of automobile condenser fans, rotors of blower motors, rotors of push rod motors, rotors of electric