English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

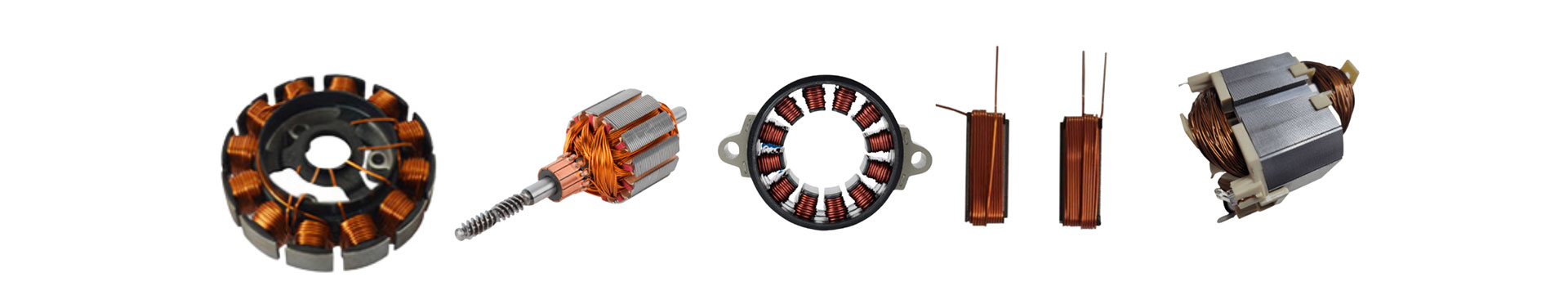

Rotor High-speed Winding Machine with Conveyor Line

Send Inquiry

PDF DownLoad

SHUAIRUI® Rotor High-speed Winding Machine with Conveyor Line

Equipment introduction:

1.This machine is used for the winding process of the rotor.

2.Equipment stand-alone operation or equipment stand-alone operation is simple and easy to operate.

3.Automatically complete the functions of winding, hooking, clamping, tearing and other functions.

4.Complete quick replacement of winding molds and fixtures within 15 minutes.

5.Applicable to a variety of different hook winding methods, such as double winding, etc.

6.The dynamic balance of the flying fork is stable, and the indexing without mold opening can be selected, which greatly reduces the winding time.

7.The equipment adopts a motion control system, which reduces the servo acceleration and deceleration time and improves the winding efficiency.

8.Servo tension control system quickly responds to provide the appropriate tension required for various actions such as acceleration, winding, deceleration, and hook indexing, which improves the stability and efficiency of winding.

9.Winding efficiency: 16S (24 hooks/12 slots/30 turns)

10.Flying fork rated speed: 4000 rpm

11.Tension control system: Servo tension control

12.Working air pressure: 0.5-0.7MPa.

13.Applicable fields: rotors of electric tools, rotors of garden tools, rotors of vacuum cleaner motors, rotors of small household appliances, rotors of water pumps, rotors of automobile condenser fans, rotors of blower motors, rotors of push rod motors, rotors of electric forklift motors, rotors of glass lift motors, rotors of motors of automobile oil pumps , car window motor rotor, printer motor rotor, sewing machine motor rotor and other fields.