English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

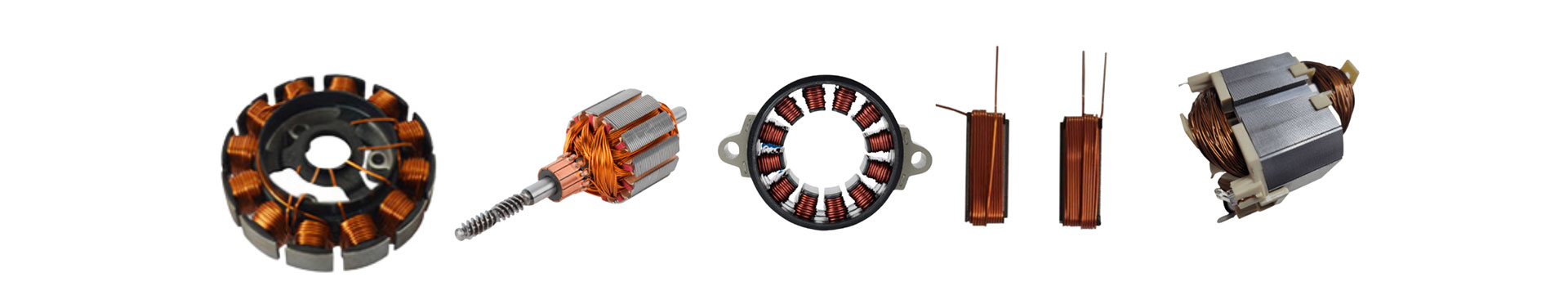

Stator Slot Lining Machine with Conveyor Line

Send Inquiry

PDF DownLoad

SHUAIRUI® Stator Slot Lining Machine with Conveyor Line

Equipment introduction:

1.This machine is used for the process of inserting insulating paper into the stator.

2.It is composed of automatic paper cutting and automatic mold clamping and paper feeding mechanism, which is efficient and fast.

3.The equipment has stable performance and high production efficiency, reaching the international level of similar models.

4.Quickly change tooling, simple operation, convenient and reliable.

5.Configure the belt line to complete the automatic production equipment for unmanned operation.

6.Paper feeding method: The motor is used to feed the paper, and the debugging is simple and accurate.

7.Feeding accuracy: ±0.15mm.

8.Paper cutting method: pneumatic cutting.

9.Pressure wheel structure: The integral pressure wheel is easy to disassemble and install, and it can jump to small and high precision.

10.Punching method: automatic cylinder punching.

11.Number of stator slots: 2 slots.

12.Production cycle beat: ≤7 seconds 1 cycle.

13.Working air pressure: 0.5-0.7MPa.

14.Application areas: stators for electric tools, stators for garden tools, stators for vacuum cleaner motors, stators for small household appliances, stators for sewing machines, etc.