English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

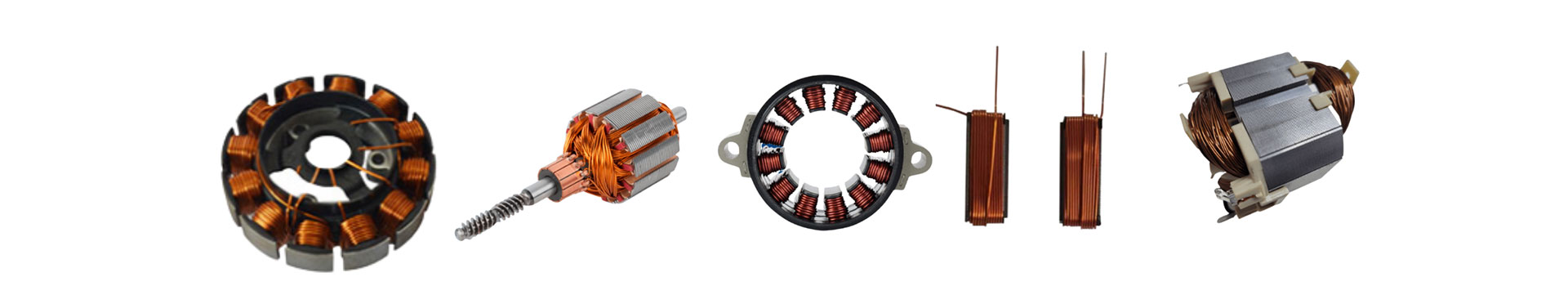

Rotor three-in-one press process: the core of efficient rotor manufacturing

2024-11-21

In the field of rotor manufacturing, the rotor three-in-one press process is a key technology. It mainly includes three important parts: shaft entry, end plate entry and commutator entry.

Shaft entry

Shaft entry is the basic link. High-quality shaft material is the premise, and its parameters such as size and hardness are strictly screened. When the press is operated, the precise positioning system guides the shaft to accurately embed into the center of the rotor core, and the pressure is precisely controlled to ensure that the shaft and the core are closely connected, laying a solid foundation for the stable rotation of the rotor.

End plate entry

The quality of the end plate affects the stability of the rotor. When entering the end plate, the end plate processing accuracy must be ensured first. During the installation process, the press fixture accurately positions the end plate at both ends of the rotor, and the pressure is evenly applied to make the end plate fit tightly with the core and shaft to prevent loosening during operation.

Commutator entry

The commutator is crucial to the functional realization of the rotor. Before entering the commutator, ensure that its insulation, conductivity and other properties are good and the size is accurate. The press installs the commutator on the shaft steadily, accurately controls the pressure and position, ensures good contact with the brush, achieves stable commutation, and helps the motor to operate normally.

The three-in-one rotor press process perfectly combines these three steps, greatly improving the quality and efficiency of rotor manufacturing and providing strong support for motor production.