English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

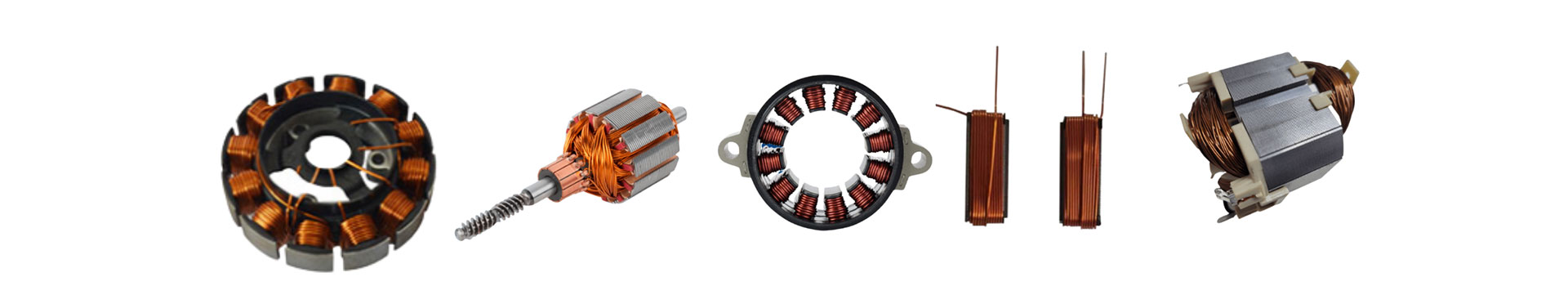

Why are brushless motors so expensive?

2024-05-10

Brushless motors are expensive mainly because of their complex production processes and high-precision manufacturing requirements. On the Brushless Motor Production Line, from the selection of raw materials to the processing of parts, every step requires strict control and precise operation.

1. Complex production process

The core components of a brushless motor are permanent magnets and electromagnetic coils. The quality and performance of these materials directly affect the overall performance of the motor. Therefore, choosing high-quality materials is key to manufacturing high-performance brushless motors, and high-quality materials tend to cost more.

2. High-precision manufacturing requirements

Many high-precision processing equipment and inspection technologies are used on the Brushless Motor Production Line to ensure that the size and accuracy of each component meet the design requirements. These high-precision equipment and technologies not only improve production efficiency and ensure the performance and reliability of brushless motors, but they also increase manufacturing costs.

3. Complex processes and tests

The production of brushless motors also requires multiple complex processes and rigorous testing to ensure the quality and performance of the motors. These processes and tests require a lot of time, manpower and material resources, thus increasing the manufacturing cost of brushless motors.

To sum up, this is why brushless motors are expensive. The Brushless Motor Production Line plays a vital role in ensuring the performance and reliability of brushless motors.