English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Products

Dc Brushed Rotor Production Line

SHUAIRUI® is a professional China Dc Brushed Rotor Production Line manufacturer and supplier, if you are looking for the best Dc Brushed Rotor Production Line with low price, consult us now!

Send Inquiry

PDF DownLoad

Product Description

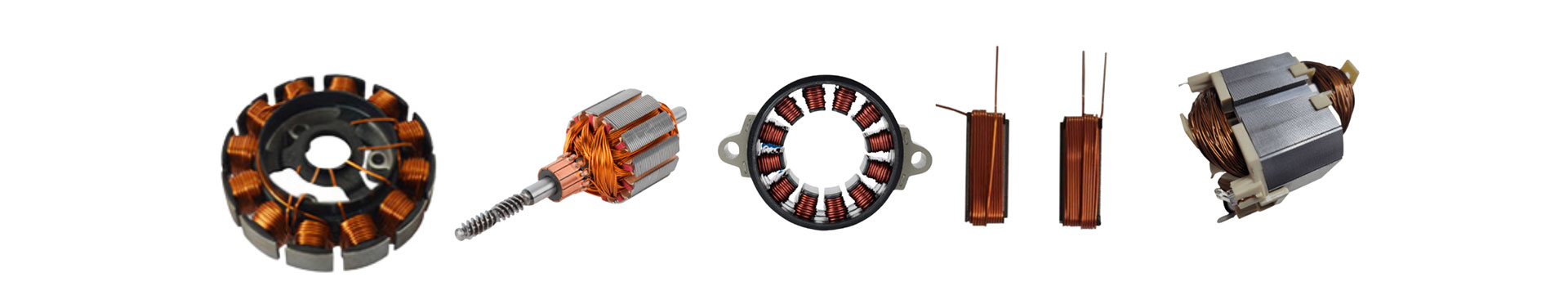

SHUAIRUI® Dc Brushed Rotor Production Line

Production line introduction:

1.The DC motor rotor production line has a high degree of automation, high stability, and supports intelligent production.

2. The staffing is 0 people, 6 seconds/1 piece, finished rotor.

3.Equipment composition: rotor feeder, commutator press machine, high-speed double-flying fork winding machine, single-head spot welding machine, online air cooling, commutator turning, deweighting and dynamic balance, comprehensive testing machine, blanking machine, etc.

4.High degree of automation, less staffing, high equipment stability, to meet mass production.

5.Intelligent production, the whole line MES system, real-time grasp of the production situation.

6.The pass rate of the whole line: 99.7%.

Hot Tags: Dc Brushed Rotor Production Line, Manufacturers, Suppliers, Factory, China, Made in China, Low Price, Cheap, Customized, Newest, High Quality

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

Related Products

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy